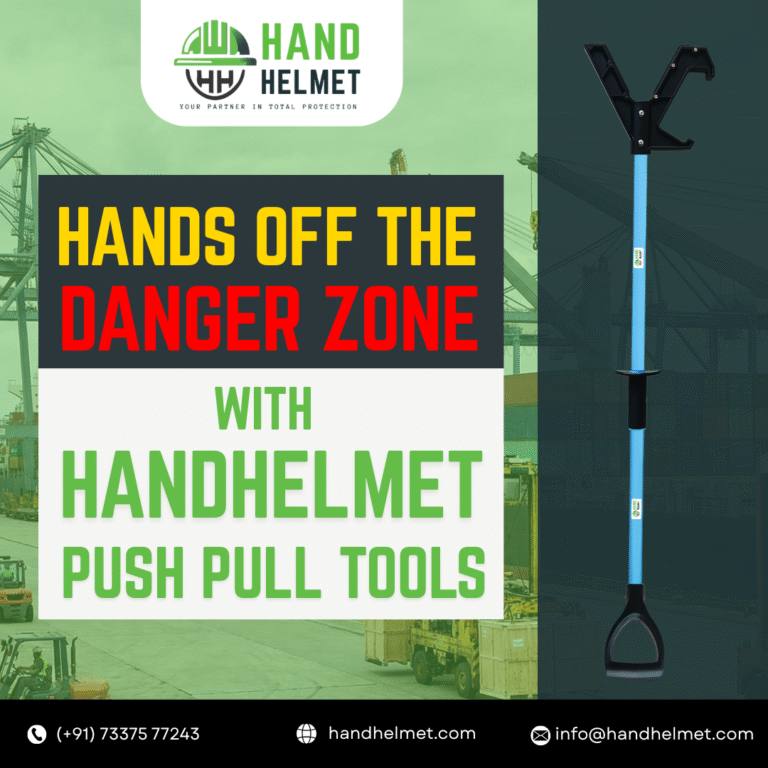

Hands Off the Danger Zone: How HandHelmet PUSH PULL Tools are Transforming Refinery Safety

“Hands Off the Danger Zone WITH HandHelmet PUSH PULL Tools”

Refineries and petrochemical plants operate in some of the most complex, high-risk industrial environments in the world. Workers routinely handle suspended loads, move pipes, align valves, or position hoses in tight, congested spaces—often near pressurized, high-temperature, or flammable equipment.

Even with strict safety protocols, hand injuries remain among the most common incidents, leading to downtime, costly claims, and compliance challenges.

HandHelmet PUSH PULL Tools are designed to eliminate these risks by enabling hands-free handling of heavy or awkward loads, keeping workers far from pinch points, crush zones, and other hazards.

Why No-Touch Tools Are Essential in Refineries

Petrochemical operations involve unique challenges:

Congested pipe racks and scaffolding

Hot surfaces and pressurized lines

Flammable or corrosive chemicals

Elevated platforms and narrow walkways

Suspended loads during rigging and maintenance

Manual handling in these conditions exposes workers to:

Pinch or crush injuries

Finger amputations

Burn hazards

Static or electrical discharge

Repetitive strain injuries

No touch tools refinery solutions allow workers to maintain full control at a safe distance, drastically reducing these risks while improving operational efficiency.

HandHelmet PUSH PULL Tools: Engineered for Safety and Precision

HandHelmet tools combine ergonomic design, industrial-grade materials, and safety engineering to meet refinery operational demands.

Key Features and Benefits

1️⃣ V-Shaped Nylon Head

Securely grips pipes, valves, hoses, and spools without direct hand contact

Provides stability during rotation, pushing, or pulling

Non-sparking material ideal for flammable environments

Minimizes surface damage on coated or sensitive equipment

The V-shape allows operators to maintain precise directional control even on large or awkward loads.

2️⃣ D-Handle Center Grip

Ergonomically designed for balanced two-handed operation

Reduces wrist strain and fatigue during repetitive tasks

Improves leverage for pushing, pulling, or guiding heavy equipment

Allows safe operation while wearing gloves in wet or oily conditions

The D-handle ensures maximum control in tight or elevated spaces, common in petrochemical layouts.

3️⃣ Center Grip — Precision Control for Landing & Alignment

Provides enhanced accuracy during placement of valves, pipes, and spools

Ideal for landing heavy loads on supports or aligning components in confined spaces

Gives operators tactile feedback without needing hand contact

Improves efficiency while keeping workers safe

This feature ensures controlled, precise movements, reducing risk of misalignment or sudden load shifts.

4️⃣ Non-Conductive Body

Eliminates electrical conduction and reduces static risk

Resistant to chemicals, corrosion, and extreme temperatures

Lightweight yet durable for prolonged use

Ideal for tasks near energized equipment or sensitive process areas

Non-conductivity ensures worker safety in electrically and chemically hazardous zones.

Real-World Applications in Petrochemical Operations

HandHelmet PUSH PULL Tools are versatile across multiple refinery tasks:

✔ Valve Handling & Alignment

Control heavy valves during installation or maintenance without putting hands near pinch points.

✔ Pipe Spool Positioning

Push, pull, or rotate pipe sections safely in congested racks or elevated platforms.

✔ Hose & Loading Arm Maneuvering

Guide hoses during connection/disconnection safely without risking hand contact.

✔ Equipment Offloading & Maintenance

Move skids, pumps, or tanks while keeping hands well clear of danger zones.

✔ Confined Space & Elevated Operations

Reach difficult areas safely and maintain control during precision adjustments.

Why Refineries Are Adopting HandHelmet PUSH PULL Tools

Eliminates hand exposure to pinch or crush points

Reduces injuries and lost-time incidents

Increases operational efficiency

Supports compliance with OSHA, ISO, and global HSE standards

Enhances worker confidence and morale

Minimizes downtime and cost from accidents

By integrating no touch tools refinery solutions, companies gain both safety and productivity benefits.

Hands-Free Handling: The Future of Refinery Safety

Petrochemical facilities worldwide are implementing zero-hand-contact policies, making no-touch handling tools essential. HandHelmet PUSH PULL Tools are leading the charge, ensuring:

Safer rigging and lifting operations

Reduced line-of-fire hazards

Compliance with stringent industrial safety regulations

Increased workforce confidence and operational precision

Conclusion

HandHelmet PUSH PULL Tools are not just a safety accessory—they are a refinery necessity. By enabling workers to maintain control without hand contact, they reduce injuries, increase efficiency, and reinforce safety-first operational culture.

“Hands Off the Danger Zone WITH HandHelmet PUSH PULL Tools.”

Your refinery. Your safety. Your solution.

👉 Adopt HandHelmet PUSH PULL Tools today and redefine refinery safety with no-touch handling.